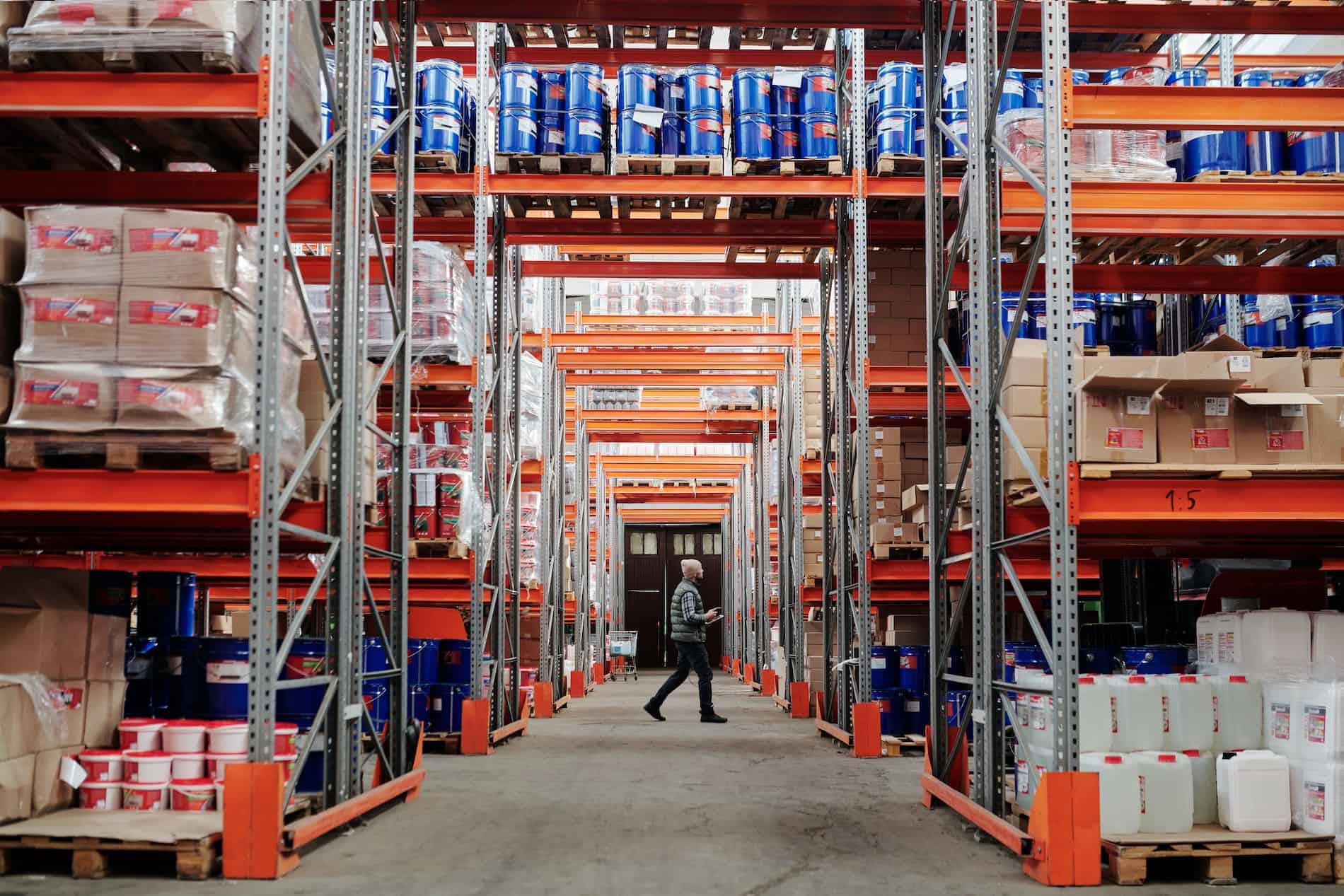

The fertilizer warehouses are concerned about minimizing damaged goods, preventing contamination, and increasing efficiency. Top Industries can help to enhance the efficiency within your fertilizer warehouse operations. They offer a comprehensive solution to enhance material handling processes like the pallet inverter, pallet changer, pallet tipper, and automated pallet transfer systems. Every product is of premium quality and has been helping a variety of sectors around the world.

Challenges the fertilizer warehouse experience

Contamination

It is essential to keep the facility uncluttered, clean, and pest-free. This can help in goods protection and safe work zones. For enhanced productivity, ensure that the cleaning process is easy and quick while staying efficient. The right pallet equipment makes the sanitation process seem effortless and leads to reduced downtime.

Increase productivity

Improving productivity on every operation level is an ongoing challenge. To attain this you will need an efficiency level ranging from decreasing downtime to fulfilling more orders along with adeptness in loading and unloading. Pair it with proper material handling tools or systems rather than depending on manual tasks.

Preserver safety

During manual movement, there are high chances of the loaded pallets slipping and falling causing workplace injuries. Even repetitive physical pressure cannot just cause back or shoulder pain, but even dampen the staff’s energy level. With machines taking over repetitive tasks, the facility becomes not just a safe workplace but boosts productivity.

Fulfill retailer demands

Manufacturers are pushed by retailers to enhance product quality and lower packaging costs, which can be passed to consumers. Manual labor, shipping miscues, and less costly packaging can put the business at risk. Manual pallet handling increases the cost and there are issues with damaged products delivered to consumers.

The rework and returns are expensive, so shipping pallets on the flatbed truck has to be safe and the consumers receive a damage-free product from the retailers. Use material handling equipment as it will eliminate the cost of getting palletized goods getting damaged as well as maintain high-quality supply chain operations.

Solutions to resolve fertilizer warehouse challenges

Pallet inverters

Pallet inverters help to lift, tilt, rotate, and transfer pallets safely and thus product loss and injuries to an employee are significantly reduced. You get pallet inverters like a single clamp, dual clamp, and ground loading in mobile, stationary, semi-automatic, and fully automatic versions.

The equipment reduces the need to unstack and restack the pallets for an exchange. Thus you can control costs, reduce damage, and lessen injuries. Every model serves different weights, heights, and movements. You can even get one customized for your warehouse needs.

Level loader lift tables

Work with level loader lift tables for ergonomic workflow. When weight is placed the level loader table lowers and rises when weight is removed. Employees work comfortably without physical strain from heavy load lifting.

Plastic pallets

For better sanitation at the fertilizer warehouse, wooden pallets must be replaced with plastic ones. Plastic pallets are light, recyclable, durable, and versatile. They are easy to clean and maintain.

Stretch wrappers

Stretch wrappers keep every packing in line and even on the pallet, which eliminates movement during transit. If the material is hazardous it is contained more safely.

Check the YouTube video of pallet inverters from Top Industries and know how it will help to enhance warehouse operations at all levels like saving time, effort, and labor costs. Keep compliant with OSHA safety standards, enhance productivity and boost consumer satisfaction.