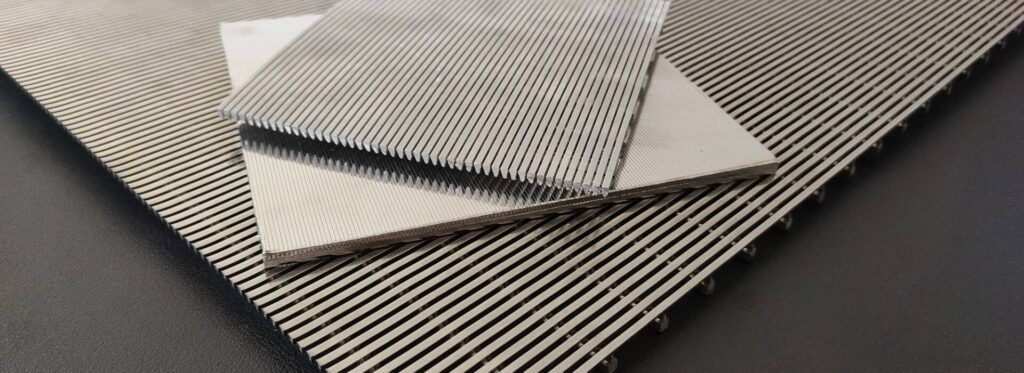

When it comes to reliable and long-lasting solutions for filtration and separation, wedge wire screen is an ideal choice. This type of screen is designed with durability and strength in mind, crafted from stainless steel and other robust metals. Its wedge-shaped profile works effectively to remove large particles while allowing smaller ones to pass through. The construction of the screen provides superior strength that ensures a lifetime of use.

Benefits: Durable and Long Lasting

The wedge wire screen is a highly durable and long-lasting option for industrial filtration. Made from stainless steel, it offers unparalleled strength and can withstand even the harshest of conditions. This makes it an excellent choice for applications where longevity and reliability are top priorities.

In addition to its durability, the wedge wire screen also boasts exceptional resistance to corrosion and wear over time. This means that not only will your investment last longer than other filtration options on the market, but it will also require less maintenance in order to maintain optimal performance.

Finally, because of its rugged construction and superior materials, the wedge wire screen is capable of handling high flow rates without sacrificing efficiency or reliability. This makes it an ideal choice for use in a wide range of industries, including mining, food processing, chemical manufacturing, and more. All in all, if you’re looking for a filtering solution that is built to last a lifetime, the wedge wire screen is definitely worth considering.

Wedge wire screen for filtration – where is it used?

Wedge wire screens are known for their rugged durability and lifetime, which makes them a popular choice in various applications. One of the primary uses of wedge wire screens is in filtration. They are used to filter out solid impurities from liquids or gases in different industrial processes such as mining, food processing, water treatment plants, and chemical manufacturing.

Wedge wire screens have become a popular choice for many industries that require highly durable and reliable screening equipment. The screens are made from high-quality stainless steel, which makes them resistant to corrosion and damage from extreme temperatures, chemicals, and other harsh elements. As a result, they have an extended lifespan compared to other types of screens available on the market.

The unique design of wedge wire screens also makes them incredibly rugged and durable. They feature an array of triangular-shaped wires that are welded together to form a V-shaped profile with narrow slots between each wire. This design allows for efficient filtration while preventing clogging or blockages that could lead to equipment failure. Additionally, the rigid construction ensures that the screen maintains its shape and integrity even under heavy use.

Overall, investing in wedge wire screens is a smart decision for businesses looking for long-lasting screening solutions. With their rugged durability and extended lifespan, these versatile screens can help increase efficiency while minimizing maintenance costs over time.

Food processing industry and others

In the food processing industry, wedge wire filters are used to separate solids from liquids during production processes like sugar refining and brewing. These screens also find application in petrochemical industries, where they help filter out contaminants from crude oil before it enters the refining process. In addition to this, wedge wire screens are also widely used for wastewater treatment that involves removing suspended solids and pollutants from water.

Wedge wire screens are widely used in the filtration process due to their ability to maintain a consistent flow rate, uniform aperture, and resistance to corrosion. They are designed with a unique structure that allows for efficient particle capture without clogging or causing excessive pressure drops. This makes them an ideal choice for use in wastewater treatment plants, food processing facilities, and mining operations.

The durability of wedge wire screens is due to their construction with high-quality materials that can withstand harsh conditions without breaking down or losing functionality over time. They offer excellent resistance against abrasion, impact, and chemical attack, which makes them ideal for use in industries where high levels of wear and tear are expected. Additionally, their rugged design allows them to withstand harsh environmental conditions such as extreme temperatures and exposure to corrosive substances.

You may also like

-

Customized Treatments to Tame Travel Tension: Traveler’s Tranquil Touch

-

How To Choose Scissor Lift Tables For Your Warehouse

-

E-Invoicing: Transforming Business Transactions in the Digital Age

-

Redefining Comfort and Quality Through Expertly Managed OP Services at All Times

-

Staying Loyal Over Time Builds Strong Careers in Korean Office Culture